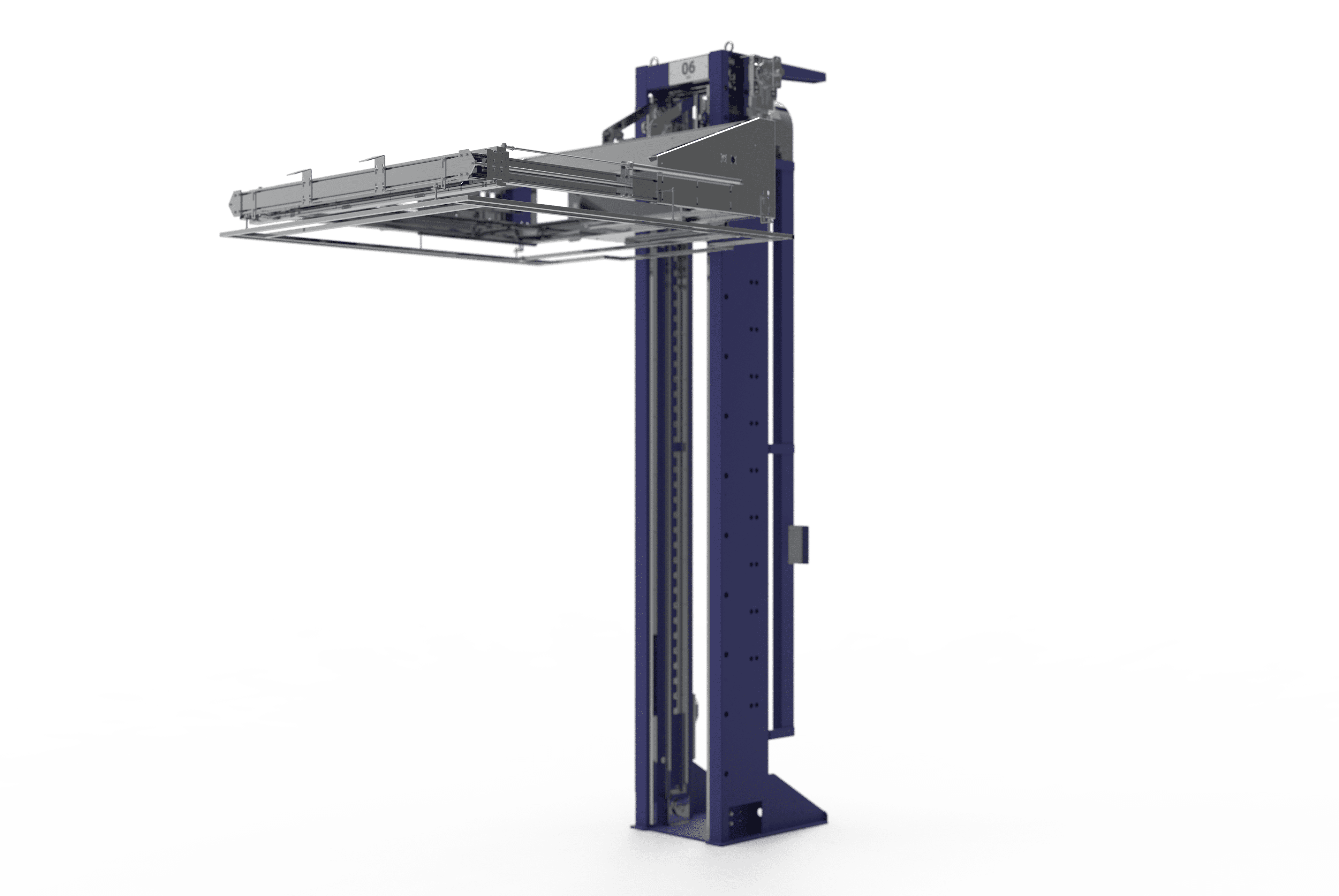

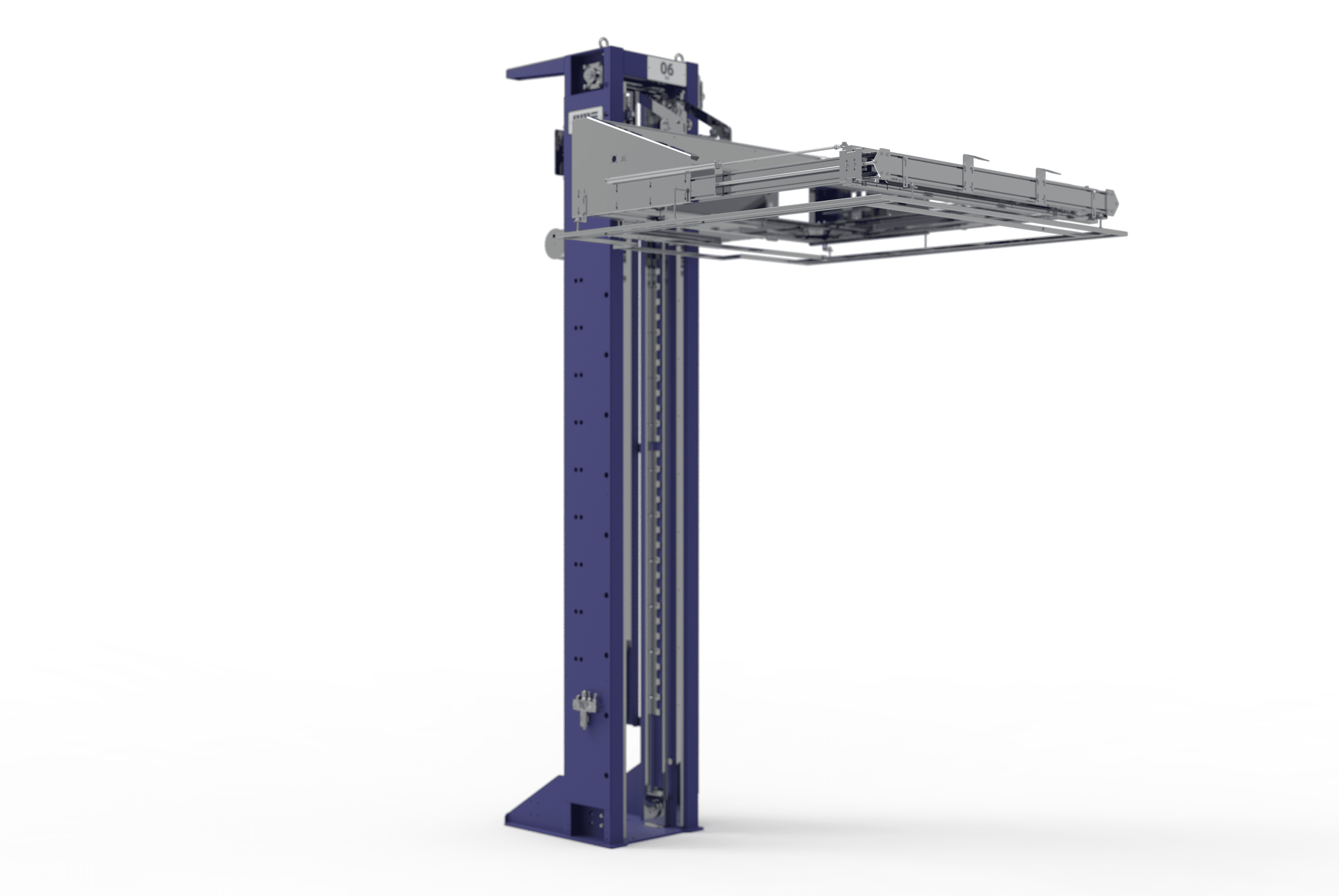

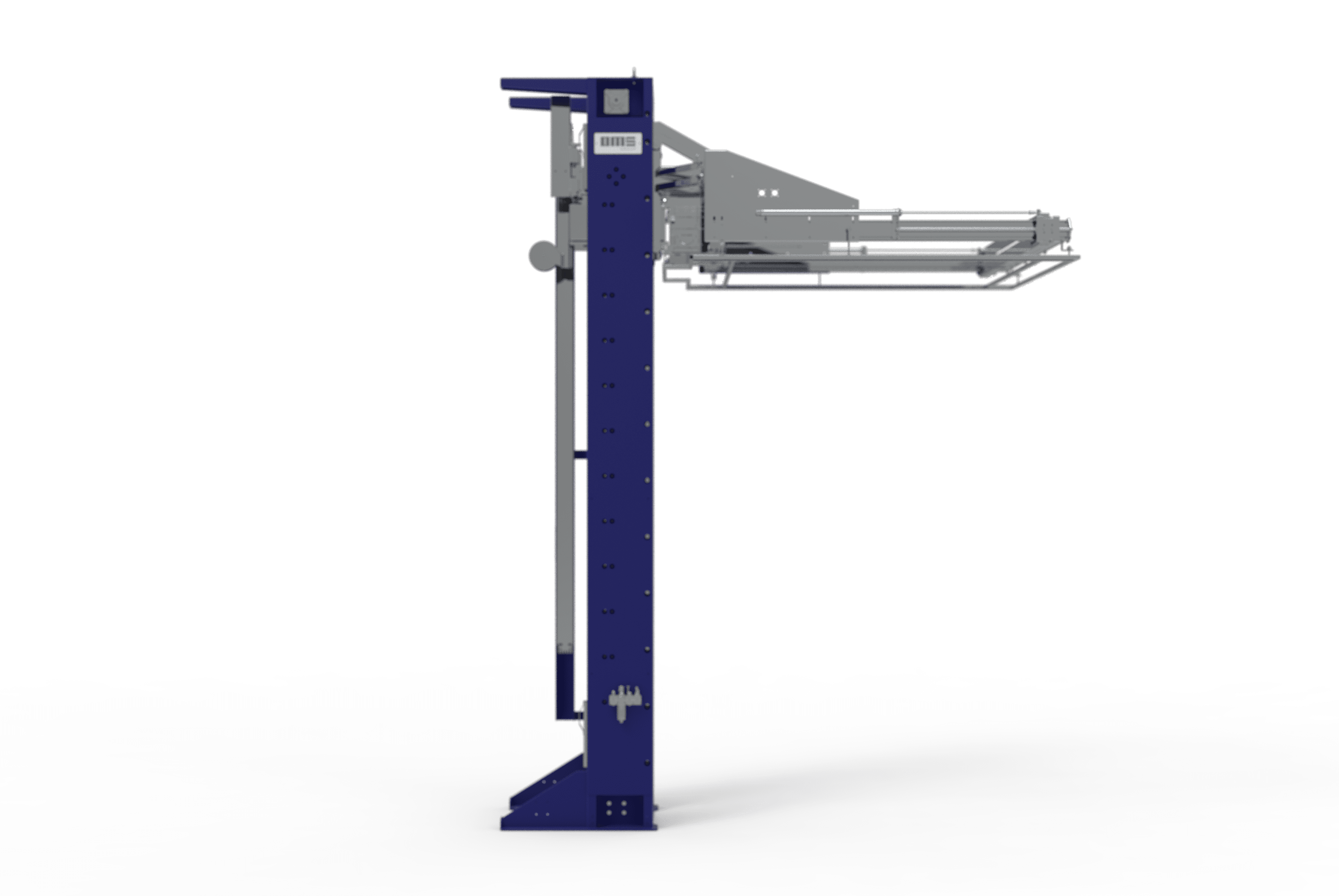

06GS Horizontal Strapping Machine

The 06GS is a horizontal strapping machine primarily used in the fruit and vegetable industry. It is designed for palletized products on automatic lines. The head feed and strap guide are operated by a pneumatic system. The arch is electrically driven and positioned laterally to the conveyor, with a chain-driven transmission. The machine’s main option is a corner application device. It can operate automatically in-line or with manual loading.

Want to know more?

Get in touch with the OMS Australasia team with any questions or enquiries.