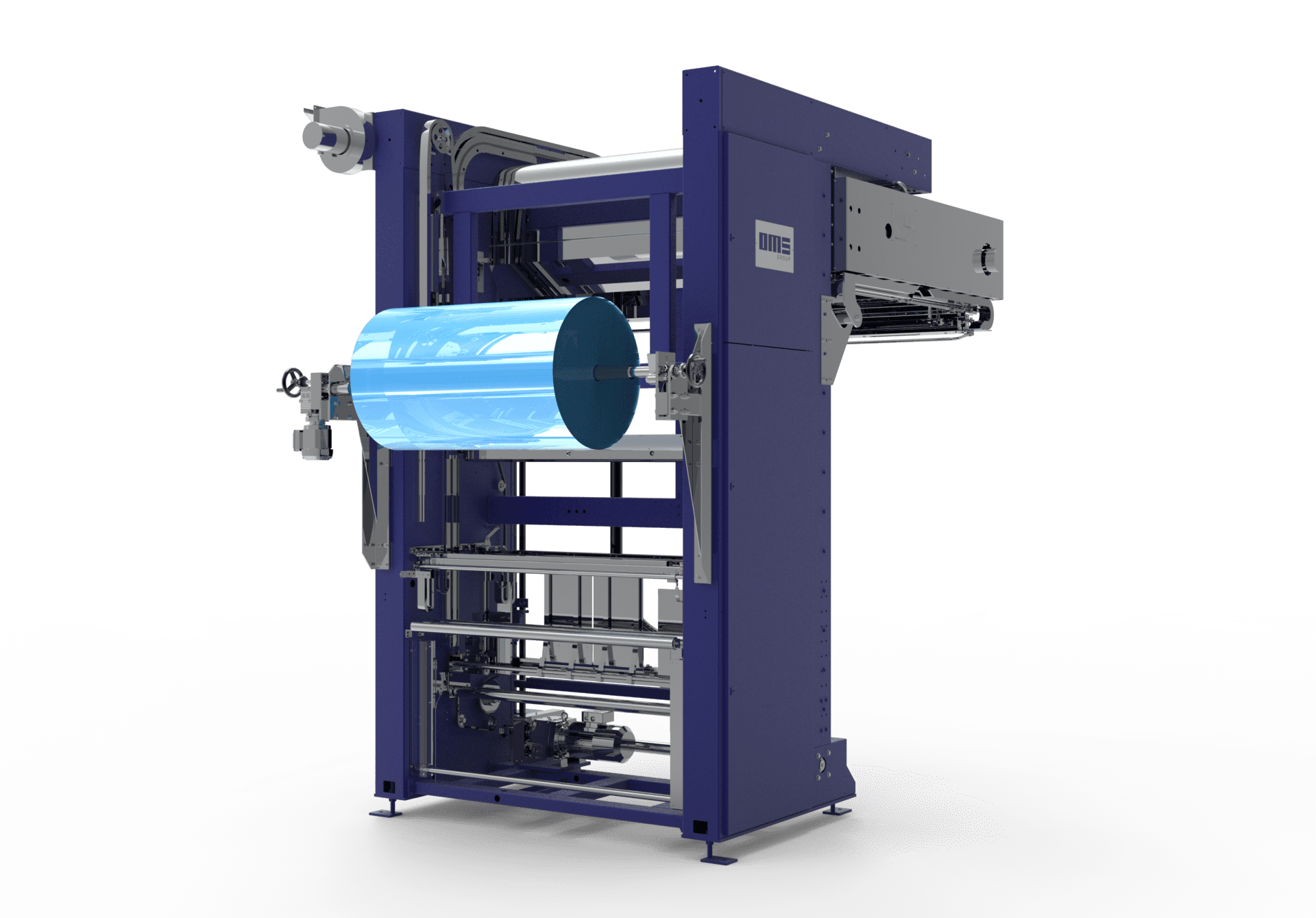

Standard Features

- Package height: 1600 mm

- Package length: 1250 mm

- Package width: 1150 mm

- Installed power: 11 kW

- Film type: polyethylene thermo

- Film thickness: 60 – 160 micron

- Coil diameter: 700 mm

- Coil weight: up to 500 kg

Want to know more?

Get in touch with the OMS Australasia team with any questions or enquiries.